SMT

SMT service items

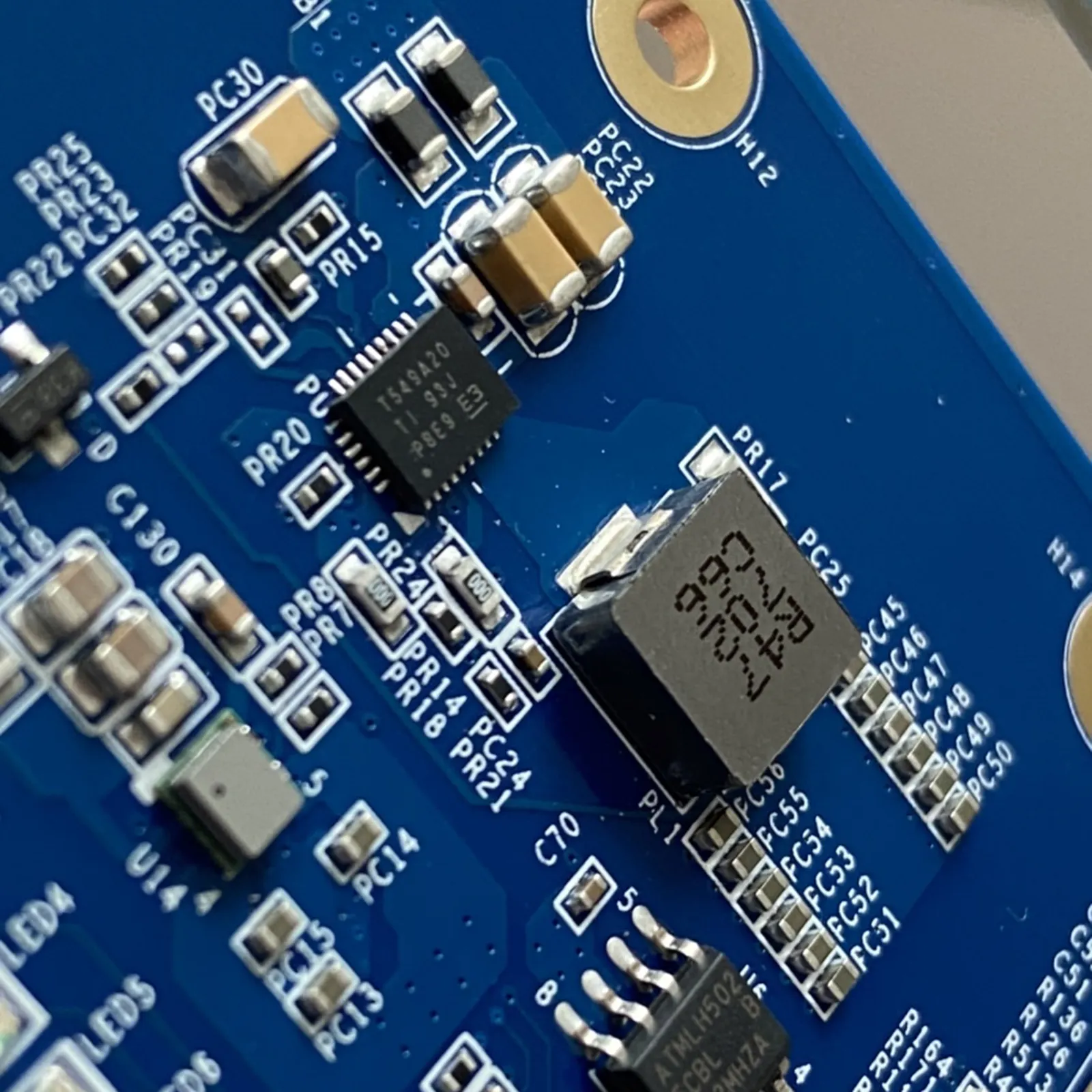

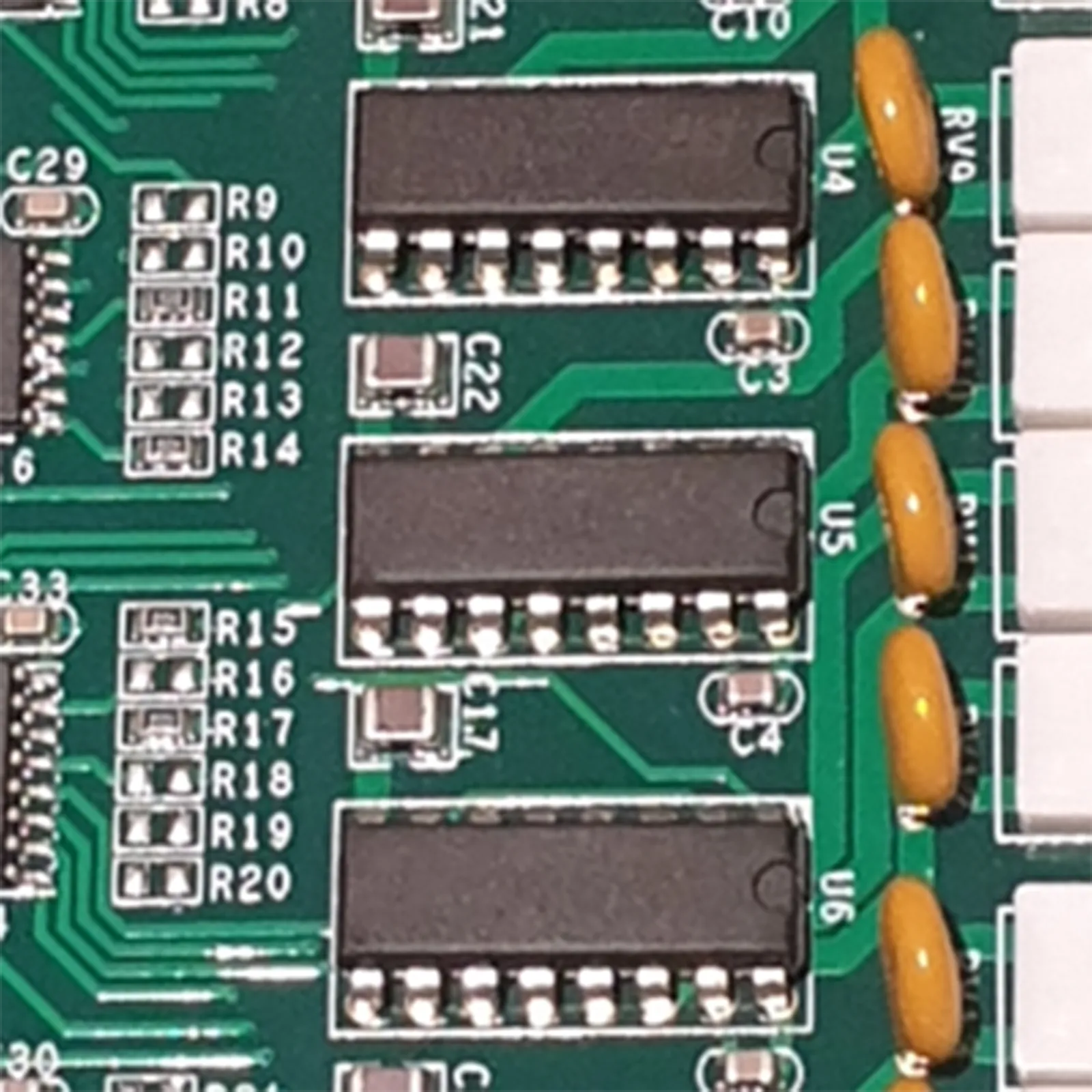

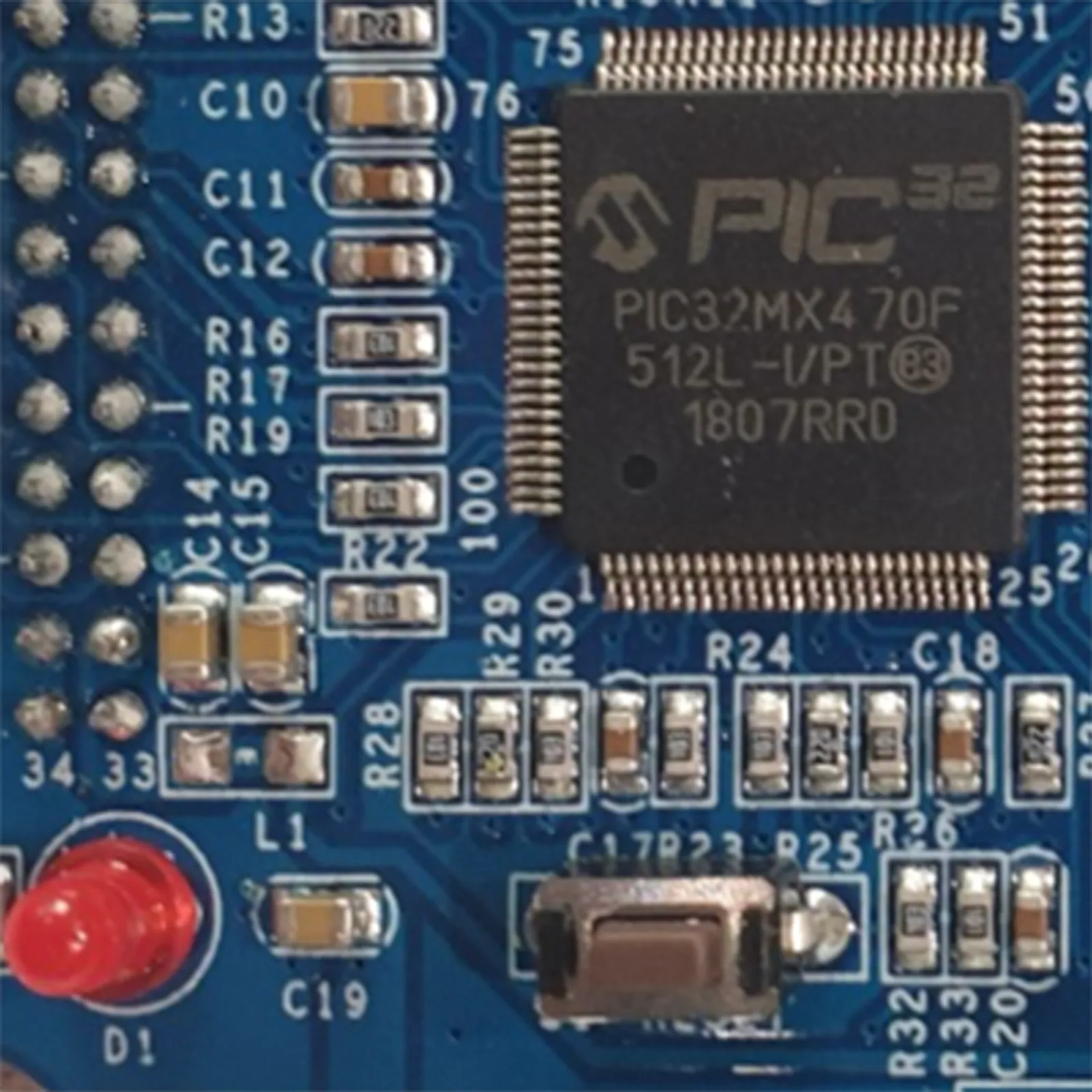

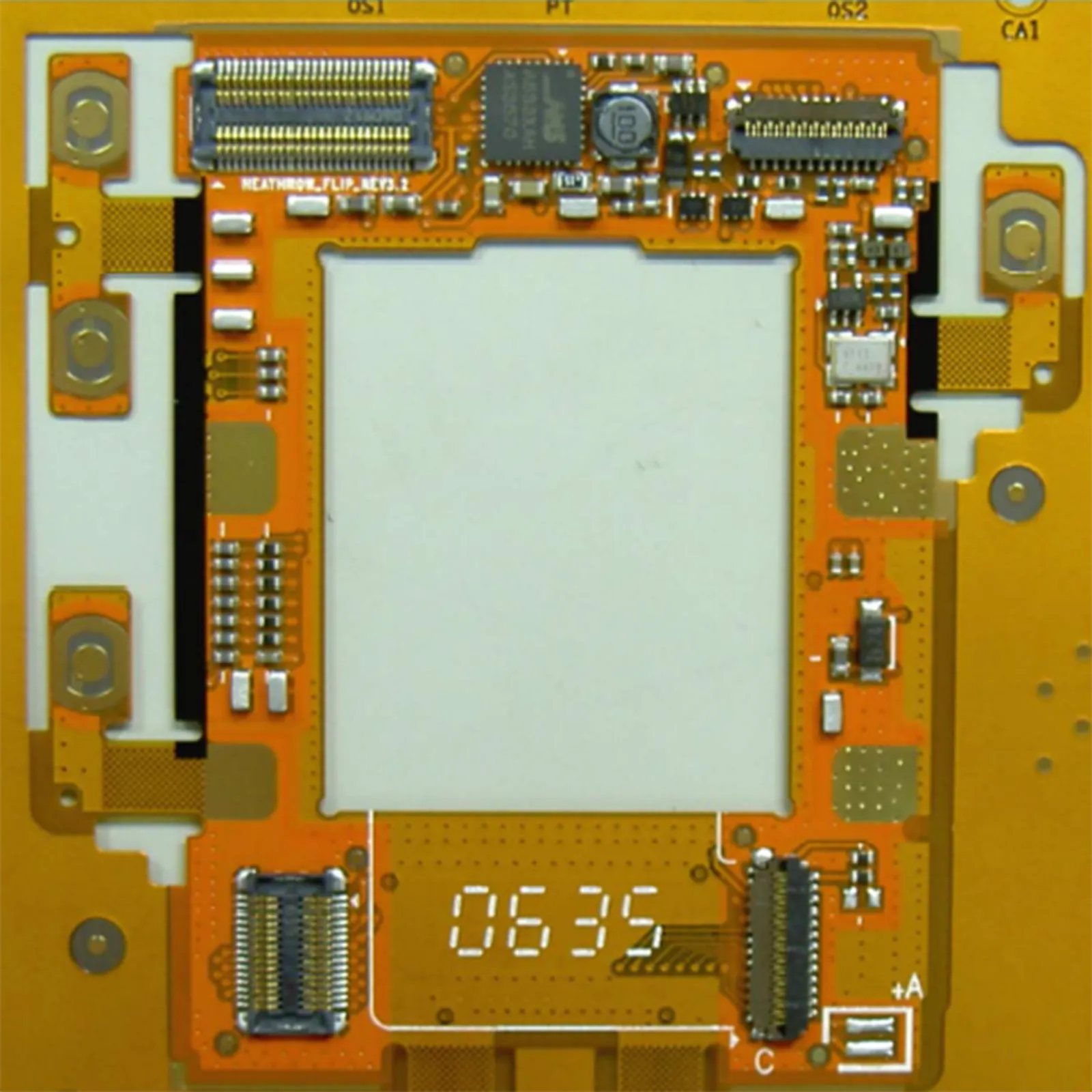

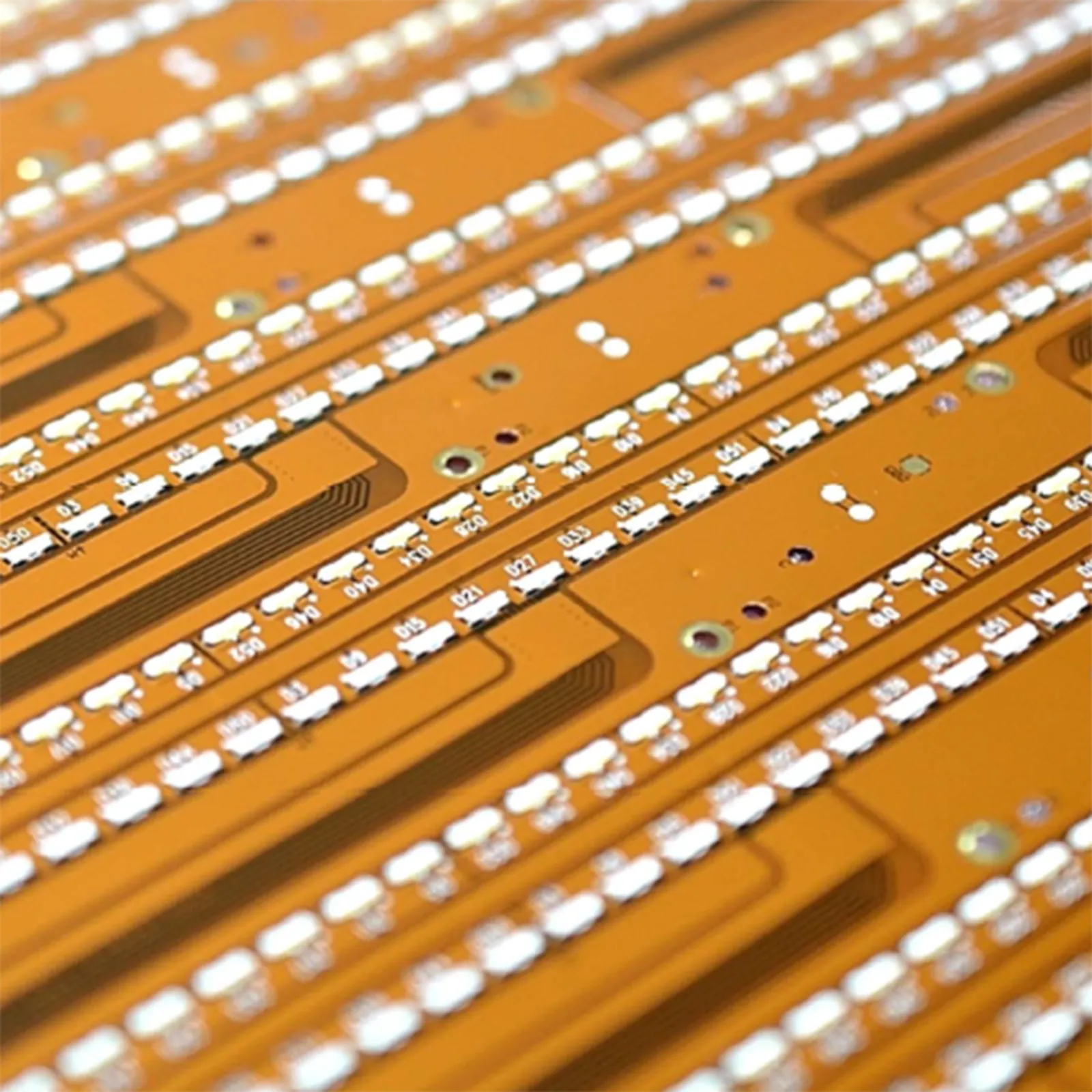

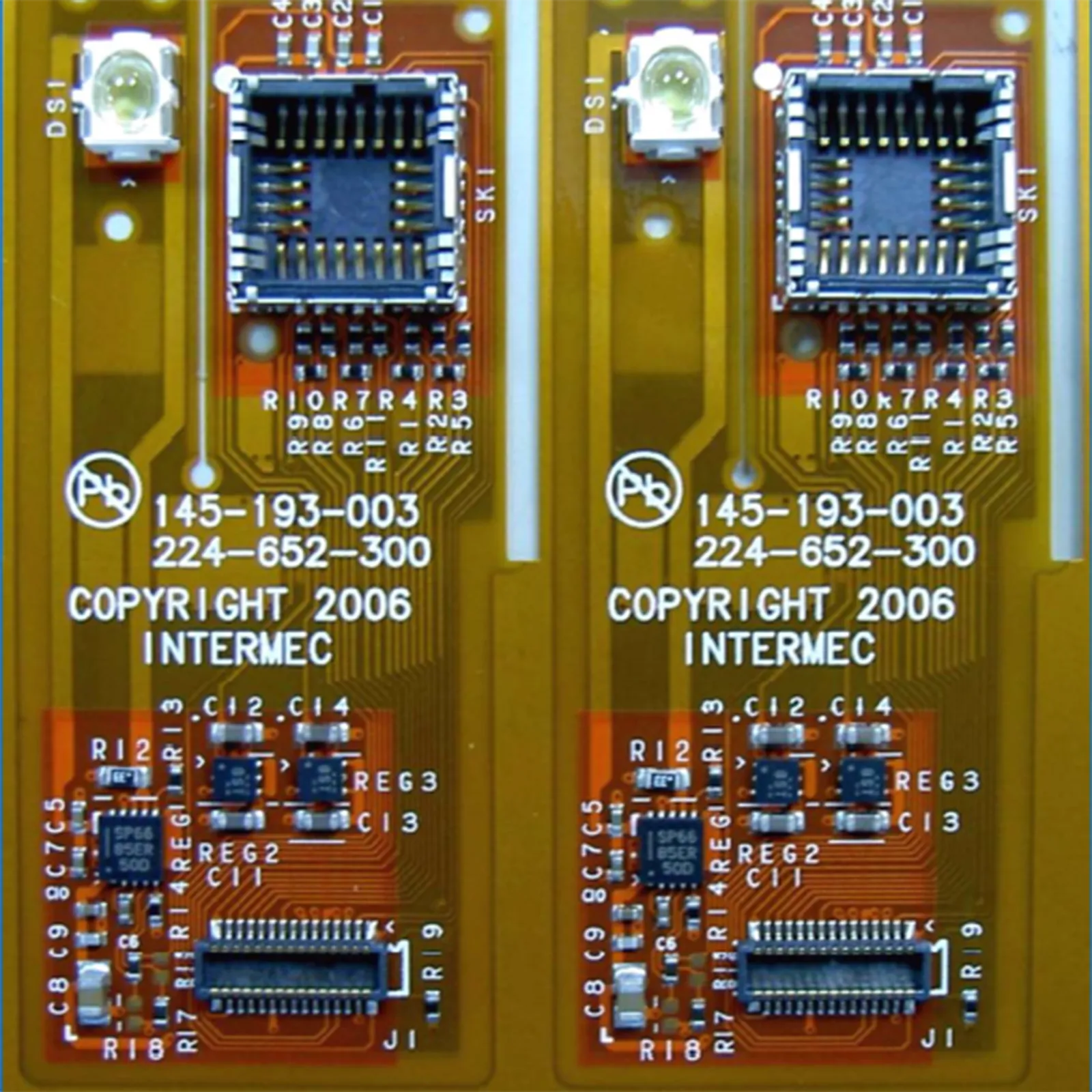

SMT

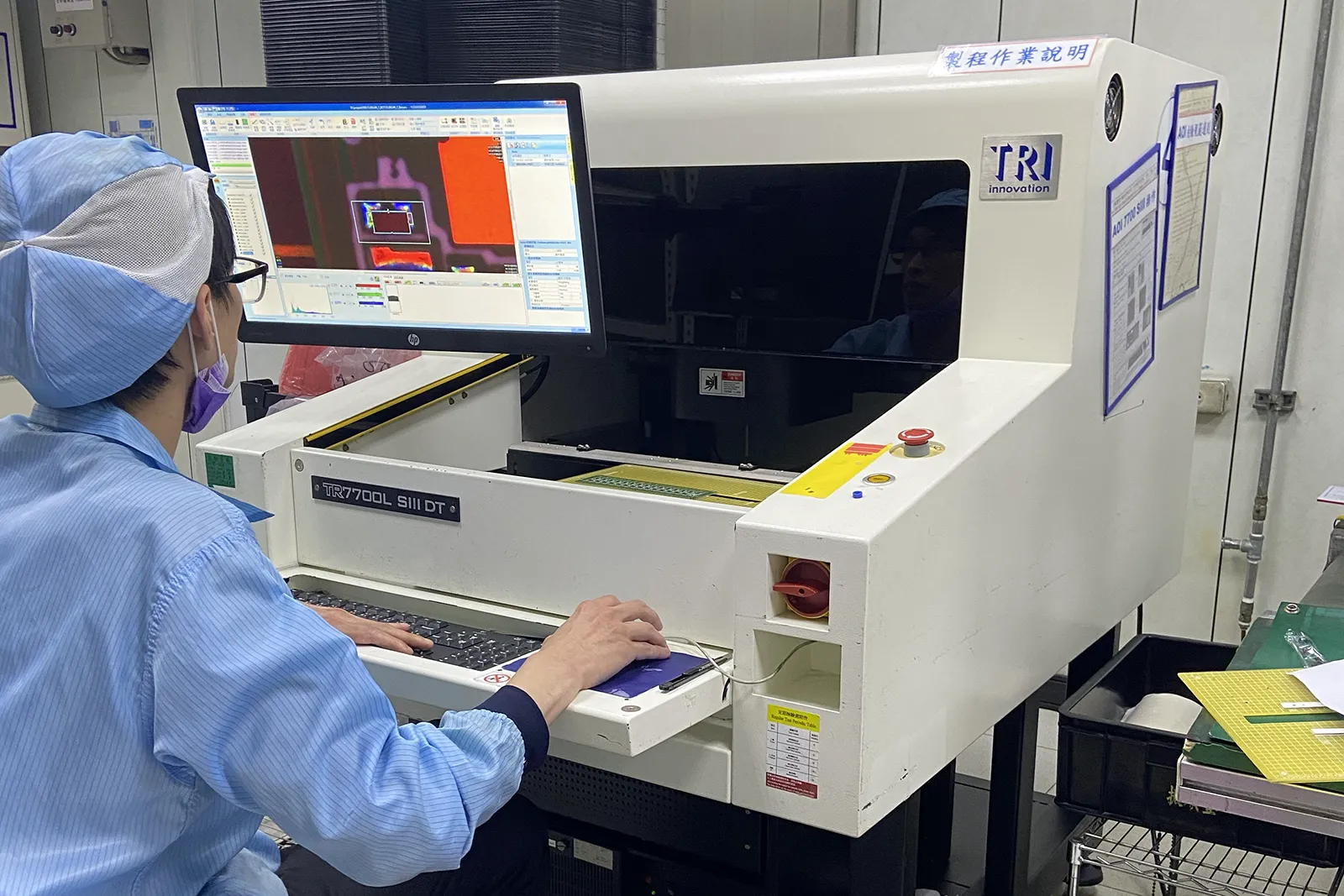

Inspection and test

Back end process

Assembly

CASE

Applications and cases

Water level gauge

Automotive control panel

Automotive control panel

Military spec controller

Test equipment

Test equipment

Electronic door lock

Connector

Fpc Light Bar

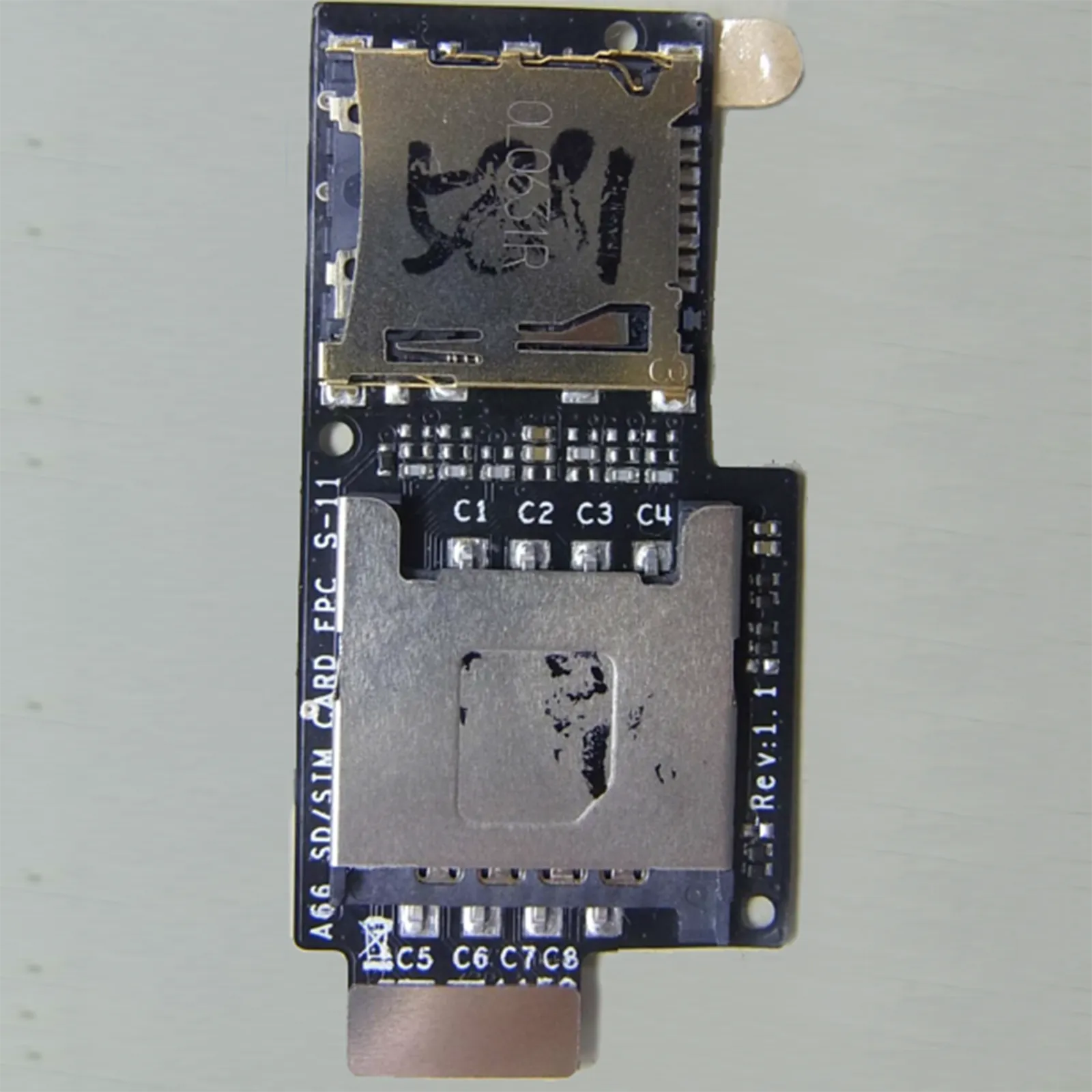

Sim Socket

Socket

SMT Process Flow

SMT manufacturing process

Preparatory work

Get document

Make stencil

Make carrier and fixture

Material withdrawal

lQC

Code spraying on board

Baking for board material

Make stencil

Make carrier and fixture

Material withdrawal

lQC

Code spraying on board

Baking for board material

SMT

Solder paste printing

Solder paste thickness measurement

Furnace temperature measurement

Equipment material loading

Article placement

Inspection

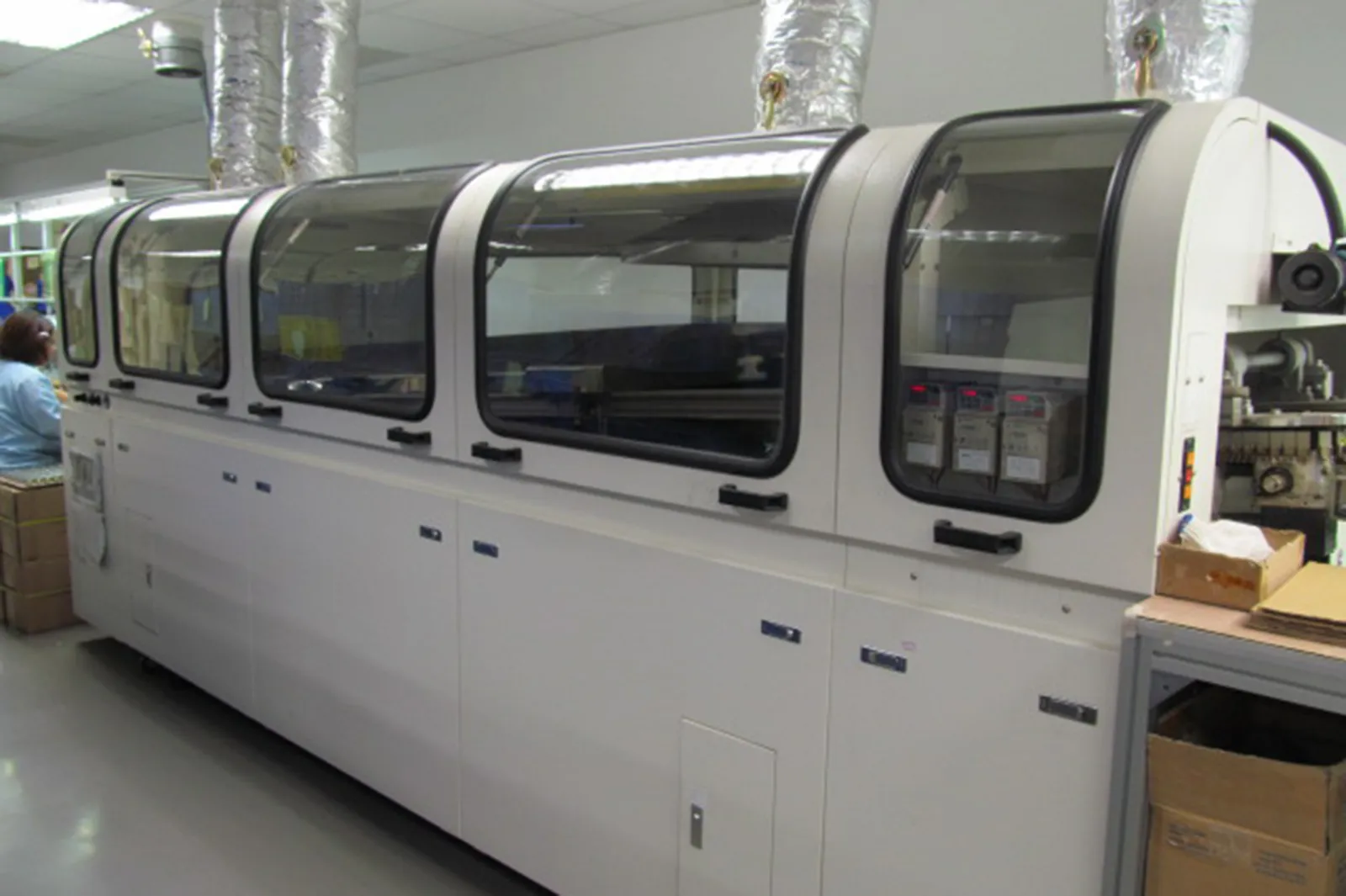

Reflow

Inspection

FQC

Solder paste thickness measurement

Furnace temperature measurement

Equipment material loading

Article placement

Inspection

Reflow

Inspection

FQC

Back end process

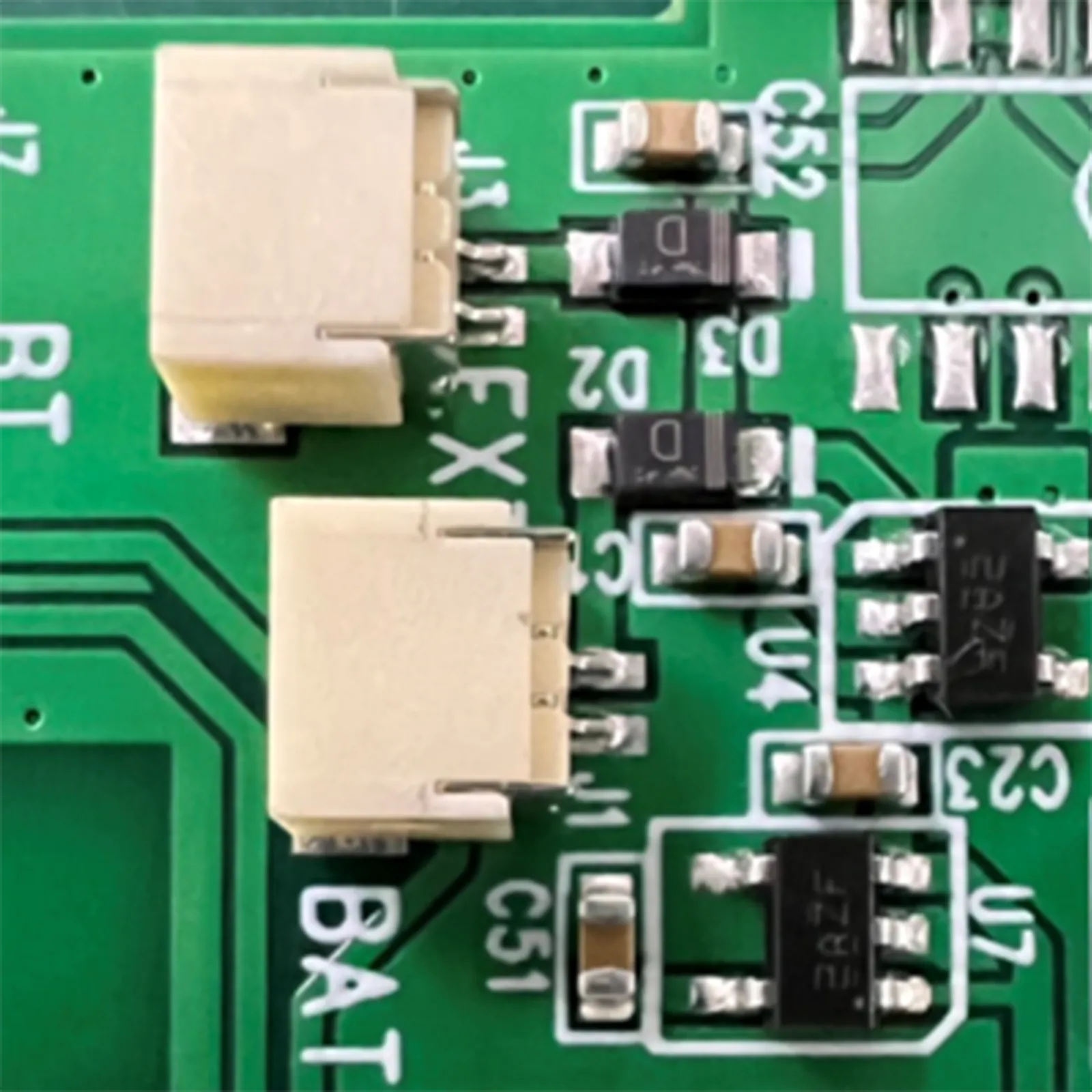

DIP

Electrica Test

Dispensing

Cutting Laminates

Back glue attach

Assembly

Back process inspection

Electrica Test

Dispensing

Cutting Laminates

Back glue attach

Assembly

Back process inspection

Shipping

ОQС

Packaging

Transport

Packaging

Transport

Process capability

| Item | Specification |

|---|---|

| Environmental Regulations | Lead-free and halogen-free throughout the entire process |

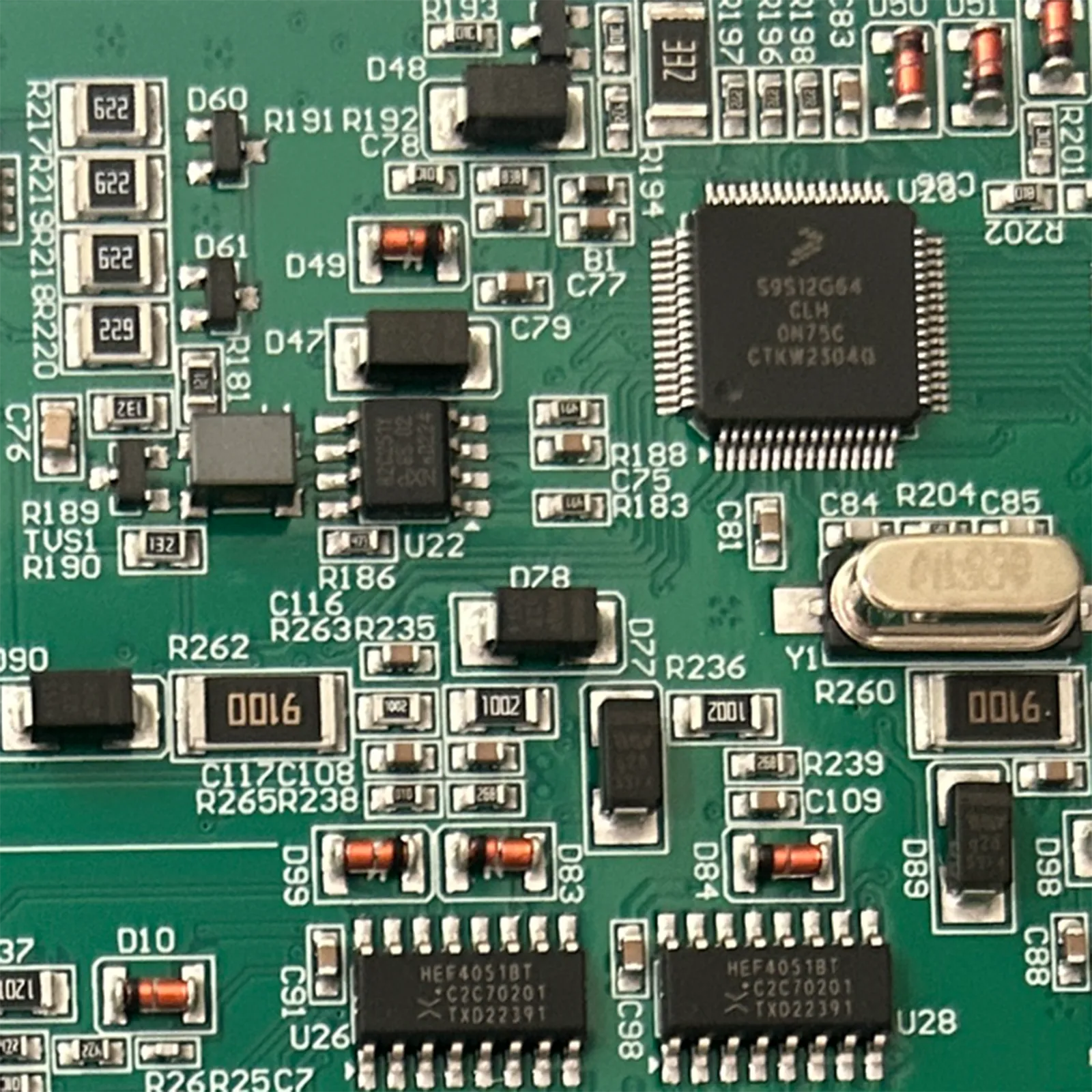

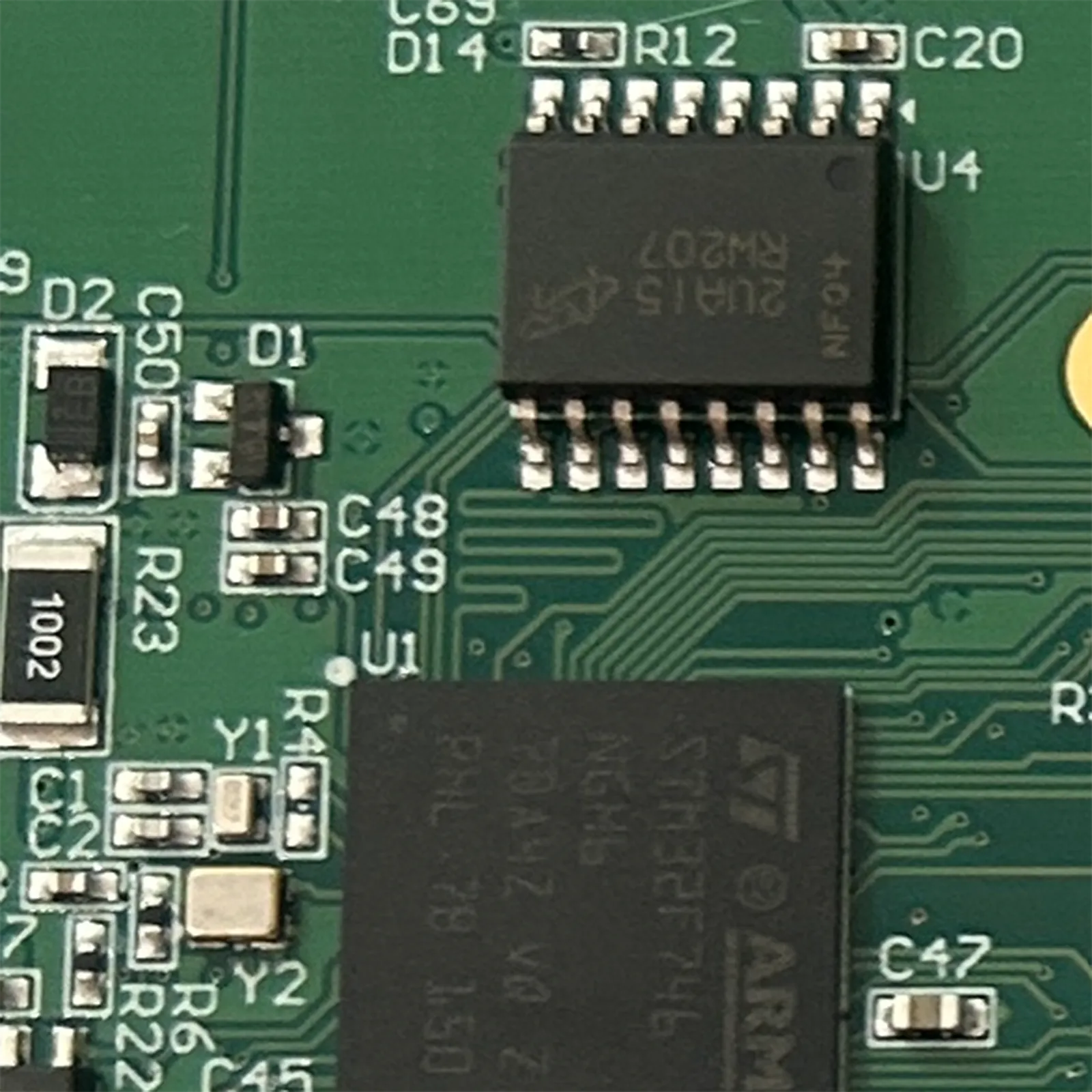

| PCB types | Single-sided, double-sided, multilayer boards, aluminum substrate, flexible printed circuit boards (FPC)... all can be produced and processed |

| Maximum Substrate Size | 600mm(L)*420mm(W) |

| Maximum Substrate Thickness | 5.0mm |

| Minimum Component Size | 01005Chip 0.2mm Pitch/Diameter Component |

| Component Placement Accuracy | ±0.03mm |

| Solder Paste Printing Accuracy | ±0.05mm(thickness, 0.02 for critical control) |

| Production Capacity | 4.5KK Point / Day(SMT) |

| DIP Hand Soldering Assembly Processing | YES |

| Samples can be quickly delivered for approval | YES |

| Professional full-process sample prototyping | YES |

SMT policy and Certification

Certification

ISO 9001

IATF 16949

ISO 14001

IATF 16949

ISO 14001

Environmental policy

Green production

Compliance with regulation

Pollution prevention

Continuous improvement

Compliance with regulation

Pollution prevention

Continuous improvement